Defining First Article Inspection (FAI)

First Article Inspection (FAI) is the process of verifying that a new or revised part meets all engineering, design, and quality requirements before full production begins. By thoroughly measuring and documenting the first manufactured piece, you establish a baseline that ensures every subsequent part can be produced consistently and accurately.

The First Article Inspection Process

Step 1 — Produce the first article part

Step 1 — Produce the first article part

Manufacturing creates an initial sample based on the design.

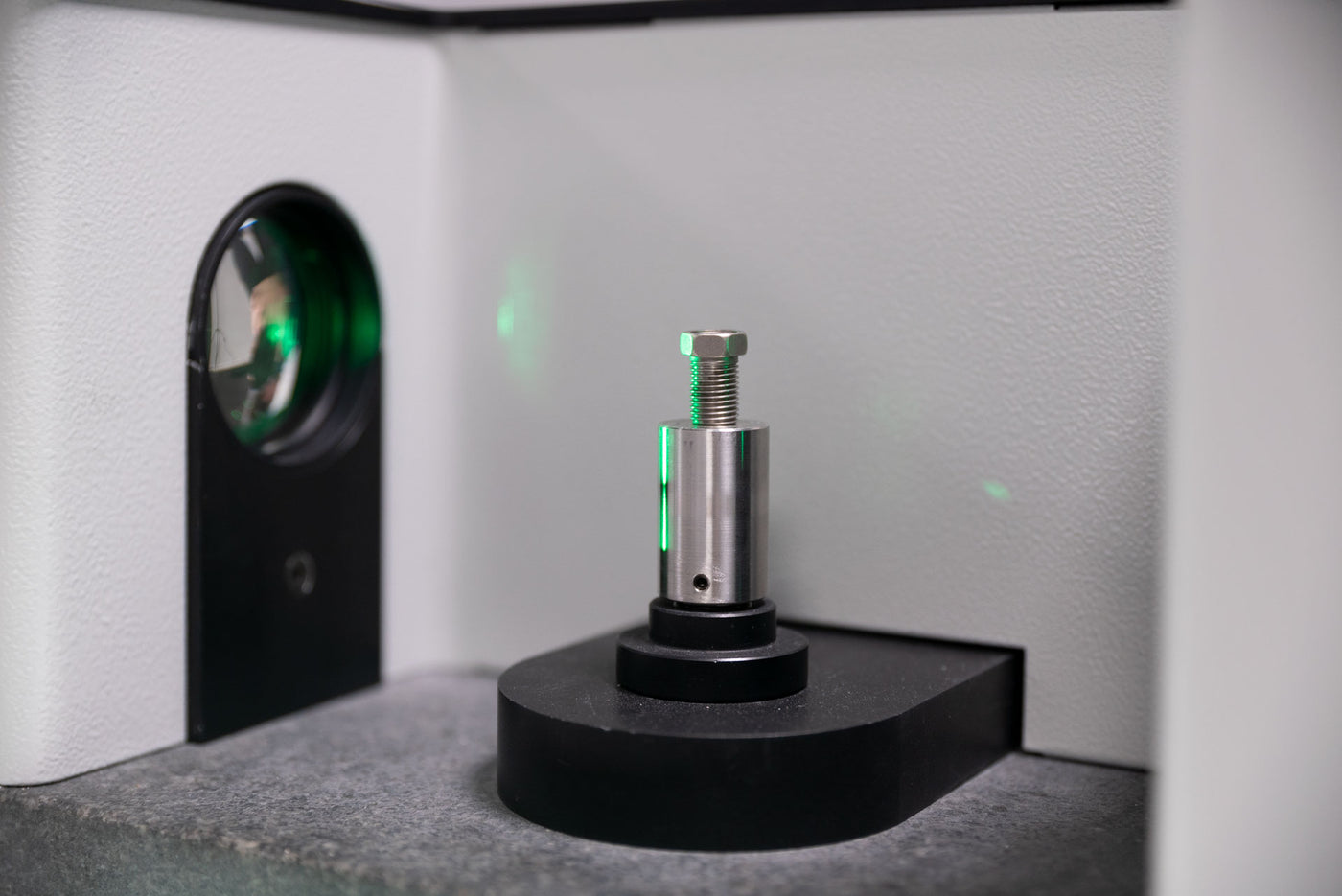

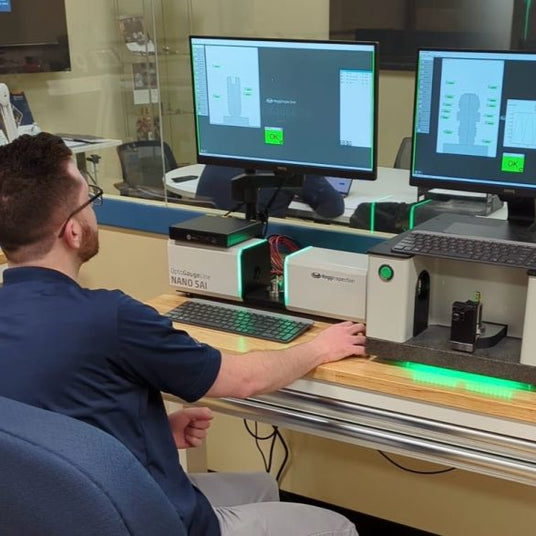

Step 2 — Measure critical features

Step 2 — Measure critical features

Each dimension and tolerance is inspected with precision tools.

Step 3 — Compare to the drawing

Step 3 — Compare to the drawing

Results are checked against the engineering specifications.

Step 4 — Document the findings

Step 4 — Document the findings

A formal inspection report captures compliance and deviations.

Step 5 — Approve for production

Step 5 — Approve for production

Once approved, full-scale manufacturing can begin with confidence.